| Project | HCM CITY URBAN RAILWAY LINE 1 |

| Contractor | SUMITOMO - CIENCO 6 Joint Venture |

| Supervision consultant | NJPT |

| Concrete supplier |

Le Phan Construction Co., Ltd Saigon RDC Co., Ltd Foreign Trade Concrete Joint Stock Company |

| Construction location | Ho Chi Minh City |

| Product used | MVN - 21ESM (Mighty 21ESM) |

Development History of U-Beams

U-beam concrete (also known as U-shaped concrete beams) was first developed in the 1980s by the Texas Department of Transportation in the United States.

U-beam concrete is typically designed and constructed to withstand the pressure and weight of subways and other heavy loads. Notably, U-beam concrete is a structural form widely adopted by contractors and investors around the world, especially in the construction of underground railway systems such as Metro lines.

With its U-shaped structure, the U-beam is commonly used to support and guide railway tracks, ensuring the Metro system operates in a stable and safe manner for both passengers and operators.

Today, U-beam concrete is widely used globally thanks to its superior structural performance and more economical cost compared to traditional beam types.

The U-Beam Concrete component of Metro Line No. 1 was implemented as part of the Elevated Section and Station Construction Package.

The Metro Line utilizes U-beam concrete for the construction of above-ground sections of the underground railway system. This structural form helps guide and stabilize the tracks while ensuring that trains operate safely and efficiently.

Key Specifications:

-

The U-beam component is part of the elevated section in Package No. 2, executed by the EPC general contractor – a joint venture between Sumitomo Corporation and Cienco6. This section spans 17.1 km in length and includes a total of 4,250 U-shaped beam segments.

-

Each U-beam was designed with a concrete strength of 45 MPa, and the construction requirements included:

-

Workability retention for 3 hours

-

Early strength of 16–20 MPa within 12 hours (to allow for mold removal).

-

-

Throughout the production process, not a single U-beam segment was rejected or damaged, earning high praise from the contractor and consultant for the consistency and quality of the work.

Supply Capability:

The entire Metro Line No. 1 project, and particularly the U-beam components, exclusively used concrete admixtures supplied by ICCI. ICCI's products met all specialized technical requirements and demonstrated strong supply capacity. As a result, the client highly appreciated ICCI’s professionalism, service attitude, and 24/7 readiness to deliver materials, ensuring that project timelines were never compromised.

Customer Approval Letter:

Customer Appreciation Letter

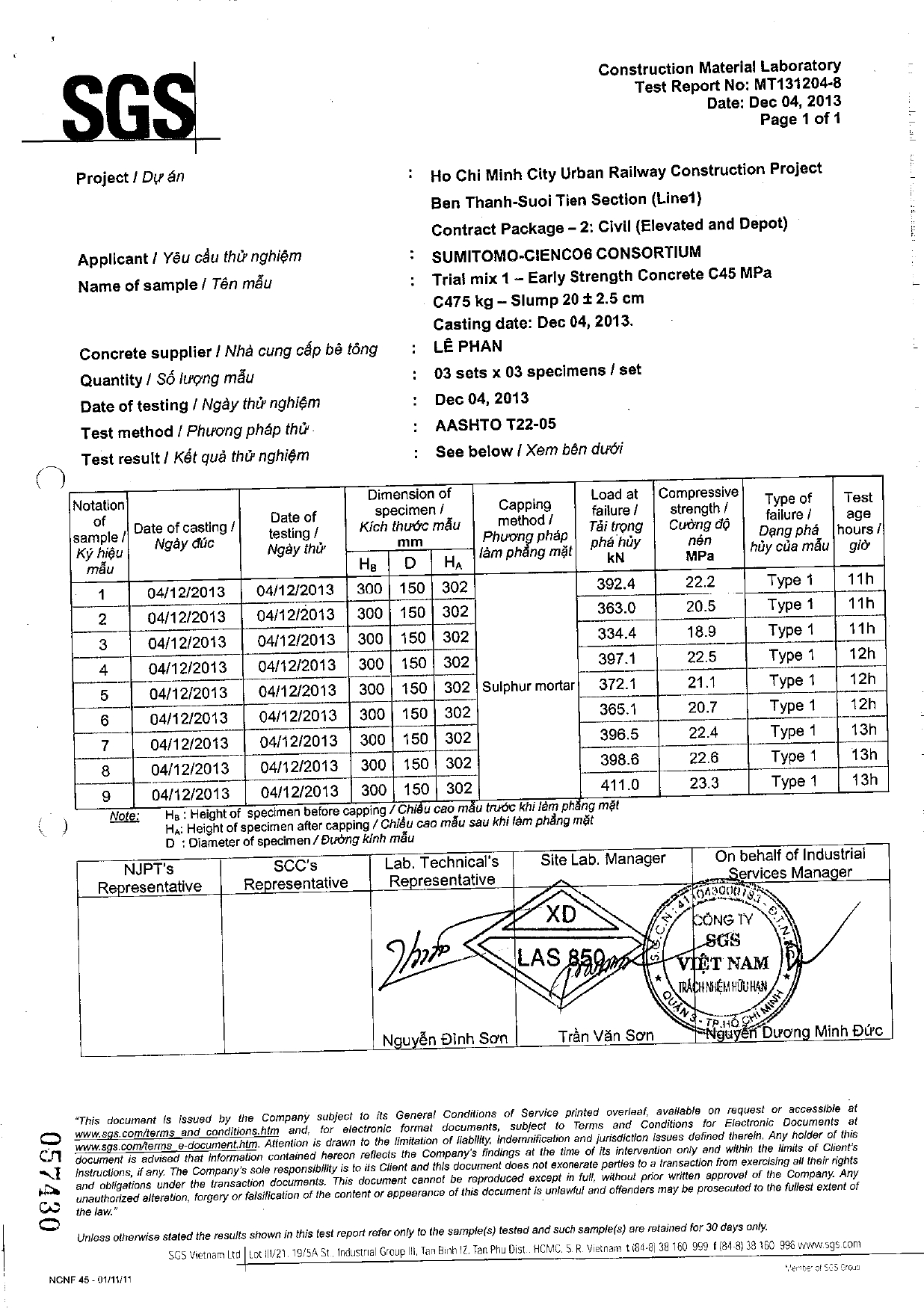

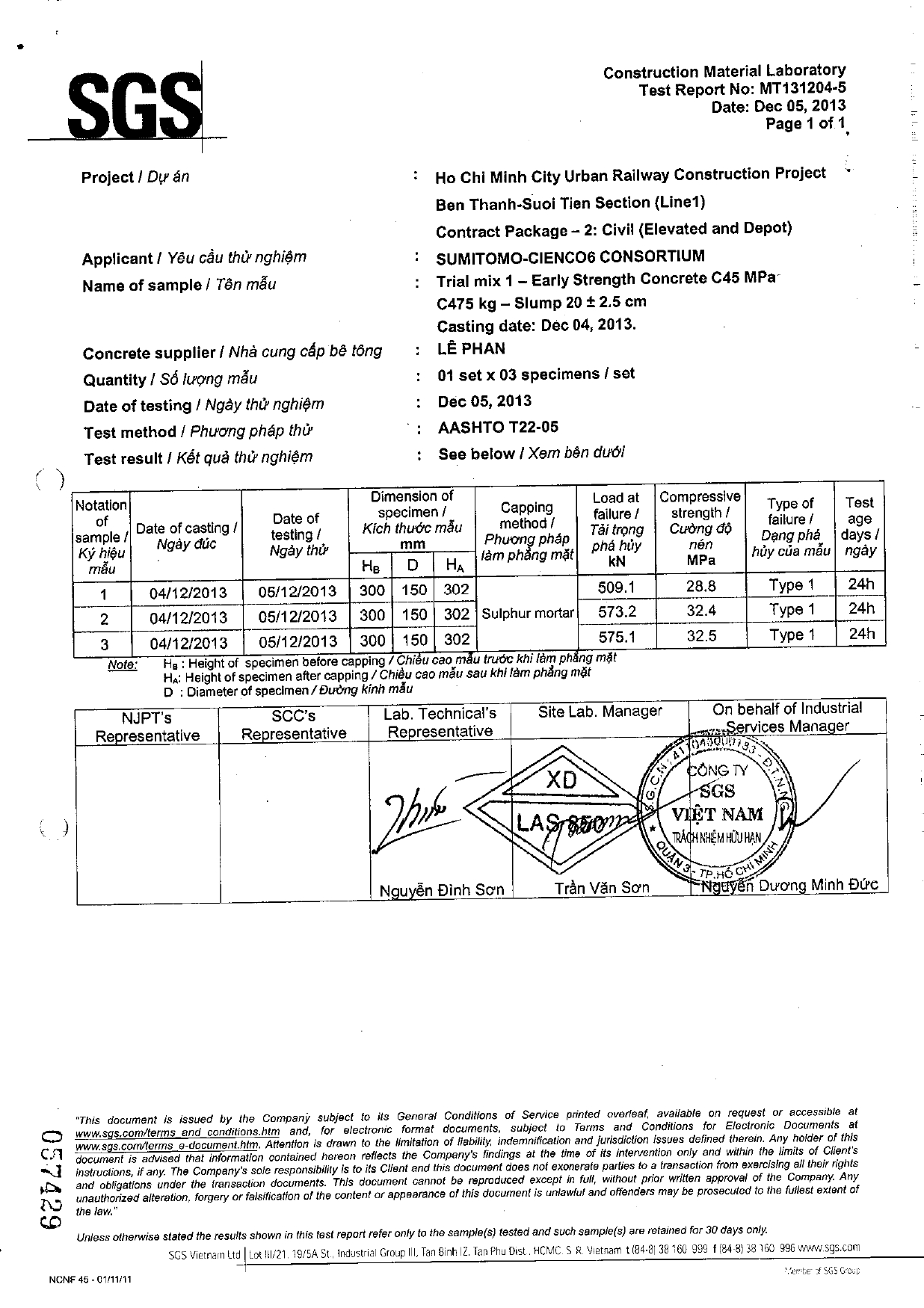

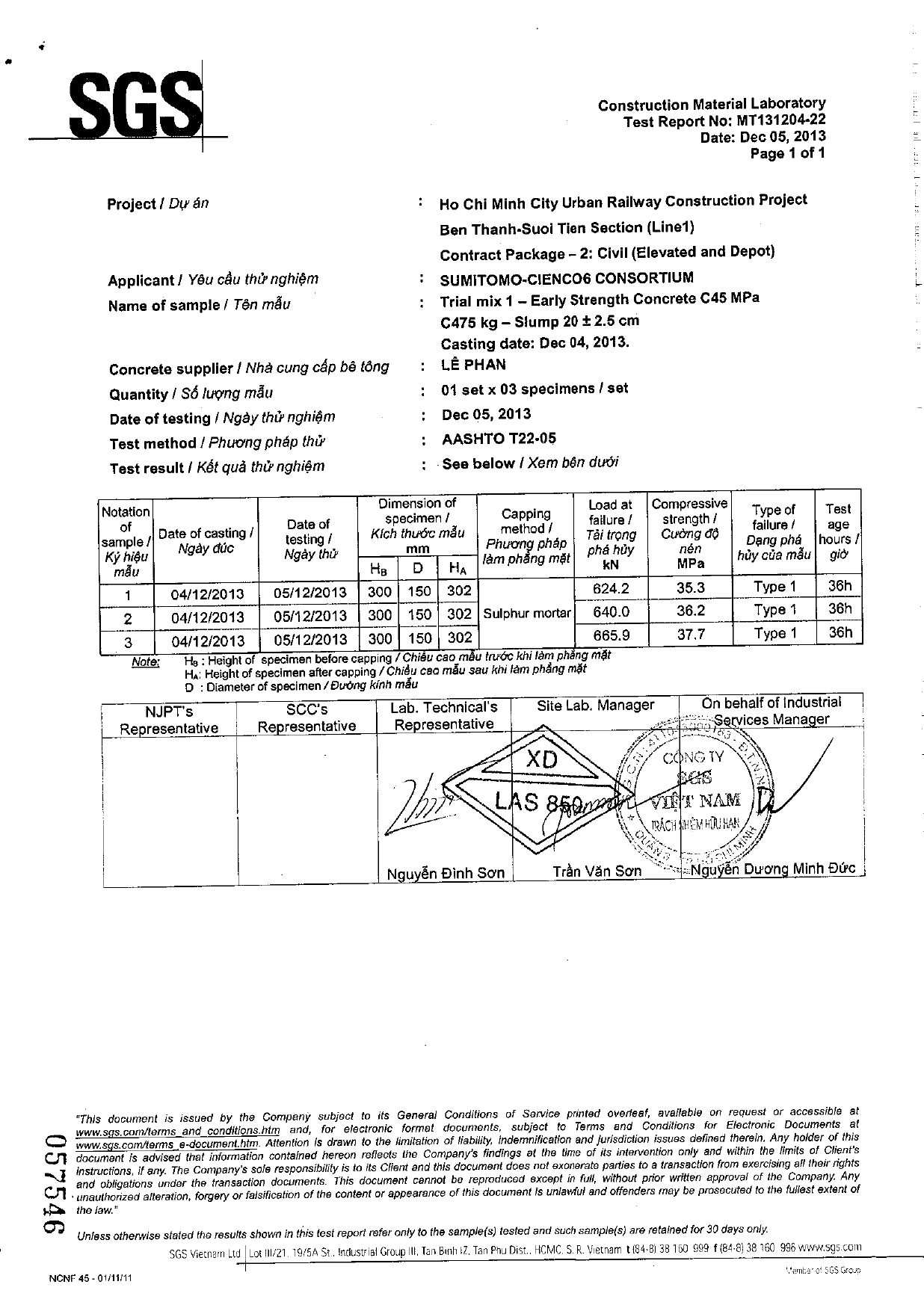

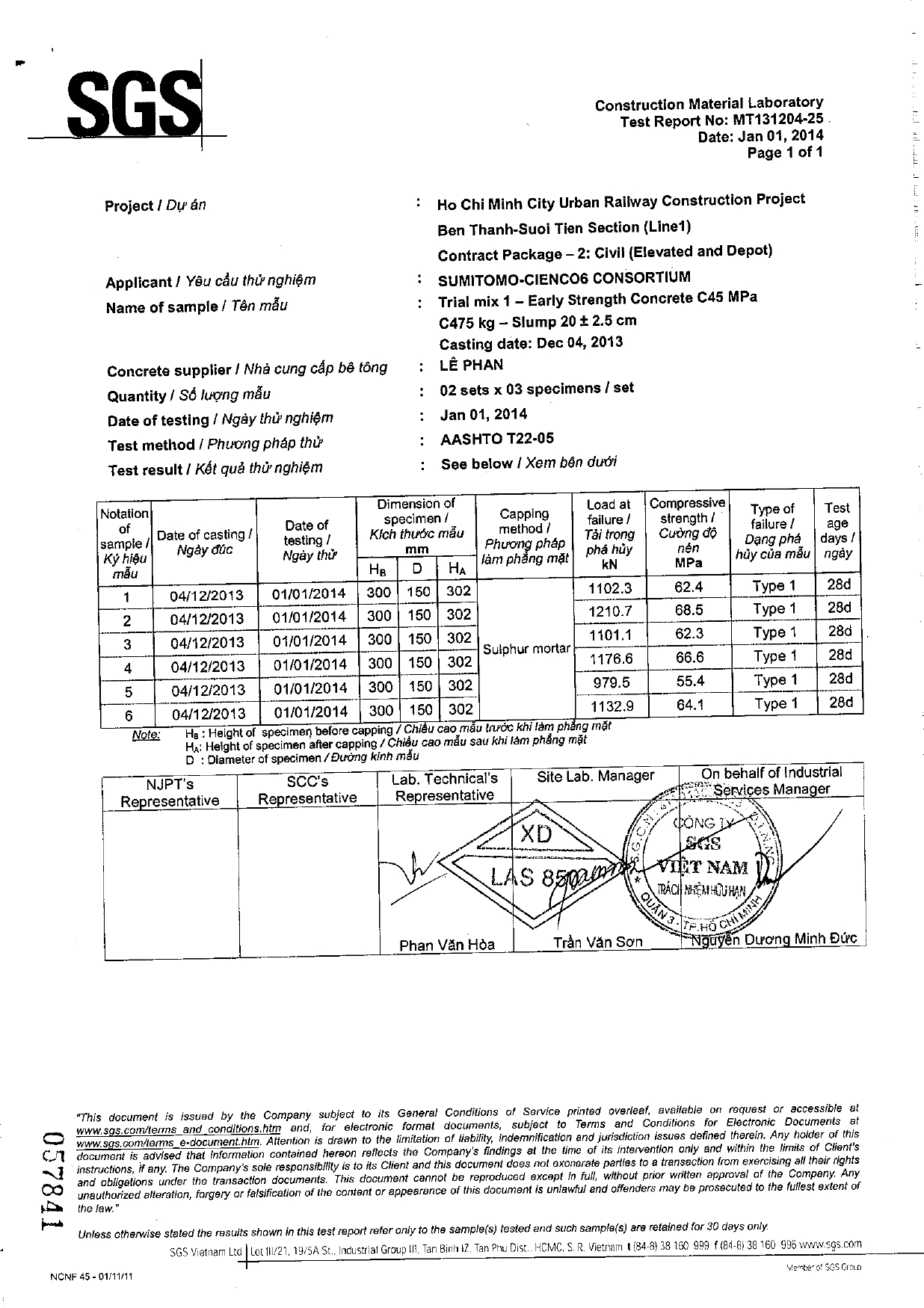

Several images illustrating the compressive strength of concrete: