MVN-3000RC

MVN-3000RC

MVN-3000RC is a 3rd generation, high performance polymer based superplasticizer for producing soft consistency high grade concrete.

Practical Uses

MVN-3000RC mainly suitable for the manufacture of concrete for ready-mix concrete and precast batching plants. MVN-3000RC is used for the following types of concrete:

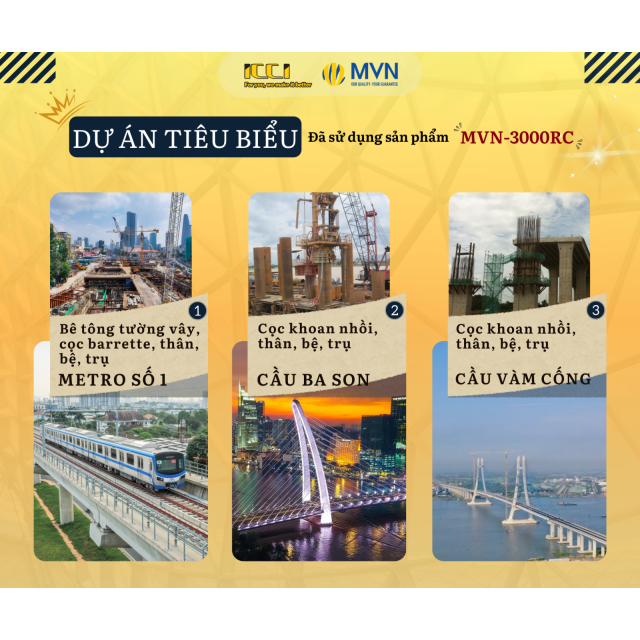

- Bored piles

- Barrette foundations and diaphragm walls

- Walls, columns, beams

- Concrete slabs in buildings and workshops

-

Contact

-

2066

Specification Type

MVN-3000RC meets the requirements of TCVN 8826 and ASTM C494 type D&G

Advantages

MVN-3000RC combines different types of effects, such as electrostatic and steric effect. The polymer molecules adsorb onto the surface of fine particles, keeping them apart while hydration progresses, MVN-3000RC effects the following concrete properties:

- Improves the cohesion of mortar phase

- Long slump keeping and high water reduction

- High workability - minimizes placing and compacting effort

- Faster evolution of strength development

- Workability can be maintained up to 3 – 8 hours

- Mitigates the effects of creep and shrinkage in concrete

Suggested Uses

- Recommended dosage: 0.6 to 1.8 L per 100kg cement/ binder.

- Typical dosage: 1.0 to 1.4 L per 100kg cement/ binder.

- Overdose: Overdosing will result in increased workability and setting time of the Concrete, however, provided that curing is effective, ultimate concrete strength and properties will not be affected.

- Quantitative: MVN-3000RC can be added directly to the pre- measured water and then added to the dry concrete mix or added separately to the wet concrete mix. To achieve the best effect of the admixture, the mixing time must be at least 60 seconds from the time the MVN-3000RC mixture is added to the batch.

- Mixing, Placing and Handling: With the use of MVN-3000RC, concrete of highest quality is being produced, however requires strict adherence to concrete technology processes such as mixing, placing,

compacting and proper curing. - Compatibility: MVN-3000RC is compatible with most Portland cements. MVN-3000RC is compatible with MVN-WPA (waterproofing admixture), Elkem microsilica (mineral admixture) and other MVN superplasticizers. Not compatible with Naphthalene-based agents.

Ecology, Health And Safety

- Toxicity: Non-toxic

- Transportation class: Non-hazardous

- Protective measures: Avoid prolonged contact with skin. Wash off thoroughly with soap water.Waste disposal: Do not dispose of into water or soil, comply with waste disposal regulations.

Refer to the product Safety Data Sheet (SDS) for more information on safe use, storage and disposal of chemical products.

Legal notes

The information and recommendations regarding product application are based on current knowledge and experience, assuming proper storage, handling, and application under normal conditions. However, due to variations in materials and actual site conditions, no warranty is provided regarding fitness for a specific purpose, nor can any legal liability be inferred from this information, written recommendations, or any other advice given. Users must independently test and evaluate the performance of product to ensure its suitability for their intended application and purpose.

General Properties

-

Chemical base: Aqueous mixture of modified Poly-carboxylates

-

Packaging: 200 L, 1000 L

-

Appearance/ Color: Pale yellow liquid

-

Shelf life: 12 months from date of manufacture if stored properly, unopened

-

Storage conditions: Dry conditions, avoid direct sunlight, temperature not exceeding 30oC

-

Density: 1.05 – 1.10 (at 25oC)

-

pH: 4.5 – 6.5